Composite bonding and glass laminating autoclave, oven, and press systems

Taricco Corporation specializes in producing advanced thermal and pressure process systems such as autoclaves, ovens, and presses. Our engineers have decades of manufacturing experience, and can custom design equipment to suit any of your composite bonding and or thermal process equipment needs.

Professional installation

Find out how our TCS control system can be integrated with your existing equipment and benefit your production requirements.

We’re confident that the TCS Thermal Control System is the control system that will meet and exceed your thermal process control requirements.

We’re confident that the TCS Thermal Control System is the control system that will meet and exceed your thermal process control requirements.

Automation & Control Systems for Industrial Processes

Including: Autoclaves, Ovens & Presses, Chemical, Petroleum, Robotics & Machines, Factory, Automation, and yes, "Out of Autoclave" composite curing as well

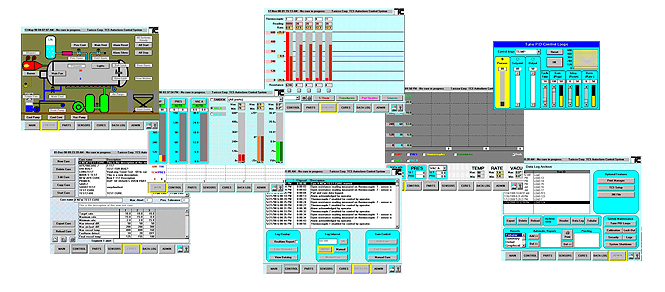

While well crafted equipment is essential to producing quality product, your control system must as capable as your machinery. Taricco Corporation’s TCS Thermal Control System is the perfect solution for autoclaves, ovens, and presses, or any batch or continuous thermal or pressure processing.

TCS gives you complete control over your process, with simultaneous control of temperature, pressure, vacuum, and any other desired parameters. It’s also tightly integrated with the mechanical process equipment, for complete fly-by-wire control. The valuable part load is continuously monitored to ensure that it’s processed exactly to your specifications, while the highly sophisticated programming cuts processing time and reduces scrap.

With its large-format graphical display, the TCS system is easy to use. It’s a native Windows application, so it uses standard personal computer hardware for easy maintainability, but no computer-specific training is needed to run the system. Operation is, for the most part, completely automatic, however if a deviation occurs, TCS gives the operators clear messages about the problem. All actions by both the computer and operators are recorded in the detailed data log that is created during every cure cycle. At the end of each run, TCS can print any of its many standard reports, as well as any desired custom reports.

Security is an important issue, especially now, and TCS provides a rigorous multi-level security system that provides tractability and complete protection against improper operation or data corruption by unauthorized personnel. There’s a supervisory software package available too, that allows remote supervision and maintenance of all the TCS systems in your plant.

Security is an important issue, especially now, and TCS provides a rigorous multi-level security system that provides tractability and complete protection against improper operation or data corruption by unauthorized personnel. There’s a supervisory software package available too, that allows remote supervision and maintenance of all the TCS systems in your plant.

Networking your TCS systems lets you share cure and part definitions among all your systems, and also makes the data generated during operation available throughout your facility. TCS uses a standard Access database, and can export cure data for analysis using an Excel spreadsheet or other means. Cure data from every run is always archived, and may be automatically stored at remote locations on the network to guarantee the safety of the valuable data.

At Taricco Corporation, our goal is to provide our clients with a control system that will enhance their quality and productivity, and the TCS Thermal Control System is capable of just that. Since the TCS software is configured, not customized, for each installation, you can always run the latest version without costly service calls.

We’re confident that the TCS Thermal Control System is the control system that will meet and exceed your thermal process control requirements.

Industrial Automation

Taricco Corporation provides complete industrial automation systems for Industrial processes and equipment.

Equipment

Autoclaves, Chambers, Ovens & Presses, Chemical, Petroleum, Food, Robotics & Machines, Factory, Automation

Processes

Batch Processes Bulk Continuous Processes Distributed Digital Control Statistical Process Control Discrete Motion

Operating Platforms:

Intel, IBM, Digital, HP, Custom Embedded Controllers.

Operating Systems:

Microsoft: Windows XP Professional , NT Server

Operator Interfaces:

Windows, X-Windows, Touch screen, Barcode, RF Scanners.

Programming:

Visual Basic, C, C++, PLC, Fortran, Machine Specific.